3D Printing: A Comprehensive How-To Guide

Welcome to our comprehensive guide on 3D printing! In this post, we will walk you through everything you need to know about this exciting technology, including its history, applications, equipment, and the step-by-step process of creating your own 3D printed object. Whether you are a beginner or have some experience with 3D printing, this guide aims to provide you with valuable insights and practical tips to help you navigate this fascinating field.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by layering material one thin layer at a time. Unlike traditional manufacturing methods that involve subtracting material (e.g., carving from a block of wood), 3D printing builds objects layer by layer using a digital design file.

A Brief History of 3D Printing

The concept of 3D printing was first introduced in the 1980s by Charles Hull, who co-founded 3D Systems Corporation. Hull invented the first 3D printing technology called stereolithography, which used photopolymerization to solidify liquid resin layer by layer. This breakthrough led to the creation of the first-ever 3D printed object, a small part, in 1984.

Since then, 3D printing has undergone significant advancements, with various techniques, materials, and applications emerging. The technology has captured the imagination of individuals, businesses, and industries worldwide due to its versatility, cost-effectiveness, and the ability to create complex geometries that were previously impossible to manufacture.

Applications of 3D Printing

3D printing has gained immense popularity and is widely used across various industries and sectors, including:

1. Manufacturing and Prototyping

One of the primary applications of 3D printing is in manufacturing and prototyping. Companies can quickly produce physical prototypes of their designs, allowing for faster iteration and improvement before bringing a product to market. This technology enables businesses to save time and reduce costs associated with traditional prototyping methods.

2. Healthcare and Medical Applications

3D printing has revolutionized healthcare by enabling the creation of patient-specific and customized medical devices, prosthetics, implants, and anatomical models. Surgeons can use 3D printed models to plan complex surgeries, reducing risks and improving patient outcomes. In addition, bio-printing, a branch of 3D printing, holds great promise for tissue engineering and regenerative medicine.

3. Education and Research

The educational sector has embraced 3D printing as a valuable tool for enhancing hands-on learning experiences. It allows students to bring their ideas to life, promotes creativity, and provides a deeper understanding of concepts in various subjects such as science, engineering, and design. In addition, researchers utilize 3D printing to develop prototypes, study materials, and conduct experiments in various fields.

4. Aerospace and Defense

The aerospace and defense industries have integrated 3D printing into their manufacturing processes to reduce weight, improve performance, and create complex internal structures. The technology enables the production of lightweight parts with intricate geometries, fueling innovation and cost-efficiency. It also allows for on-demand production and rapid repair of critical components, reducing downtime.

These are just a few examples of the many areas where 3D printing is making a significant impact. As the technology continues to evolve, its applications are expanding into newer domains, including architecture, automotive, fashion, and more.

Getting Started with 3D Printing: A Step-by-Step Guide

Step 1: Design or Download a 3D Model

To create a 3D printed object, you first need a digital 3D model. You can either create your own design or find pre-existing models from online repositories like Thingiverse, MyMiniFactory, or GrabCAD. There are also numerous 3D modeling software packages available, ranging from beginner-friendly to professional-grade options.

Step 2: Prepare the 3D Model

Once you have your 3D model, it’s essential to prepare it for printing. This involves importing the file into slicing software, such as Ultimaker Cura, Simplify3D, or PrusaSlicer. Slicing software converts the 3D model into a series of instructions that tell the printer how to construct the object layer by layer.

During this stage, you can adjust settings such as layer height, infill density, support structures, and print speed to optimize the print quality and strength.

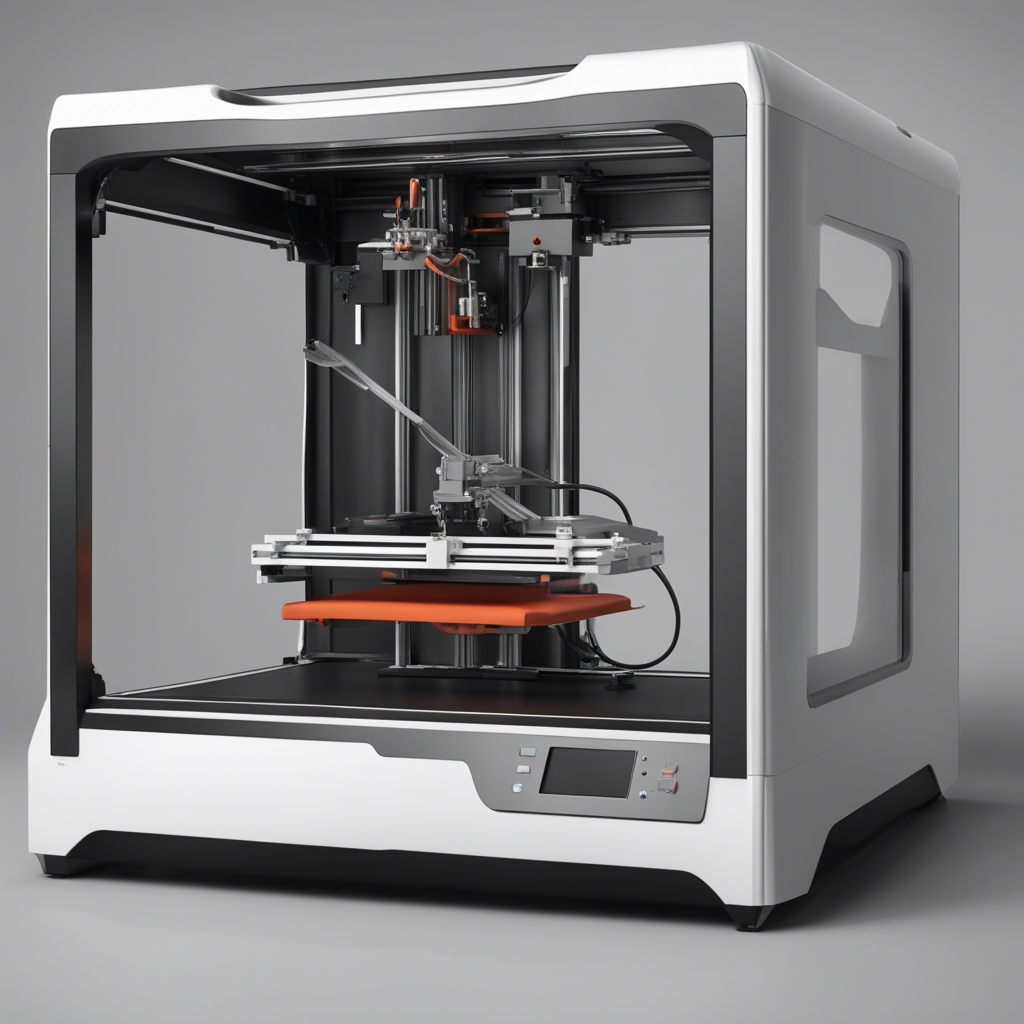

Step 3: Choose the Right 3D Printer and Material

Selecting the right 3D printer and material is crucial for achieving the desired results. There are various types of 3D printers available, including FDM (Fused Deposition Modeling), SLA (Stereolithography), SLS (Selective Laser Sintering), and more. Each technology has its strengths and limitations, so it’s important to research and choose the one that suits your specific needs.

Similarly, different materials, such as PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), and others, offer different properties like strength, flexibility, and heat resistance. Consider the desired characteristics of your printed object when selecting the material.

Step 4: Print and Post-Process

After selecting the printer and material, it’s time to start the printing process. Ensure that your printer is properly calibrated and leveled, and load the chosen material into the printer’s filament or resin tank.

Once the printing is complete, you may need to perform post-processing tasks like removing support structures, sanding, or applying finishes to achieve the desired final appearance. Post-processing requirements vary depending on the complexity of the design, the technology used, and the intended purpose of the object.

Conclusion

3D printing is a fast-growing technology with applications in various industries and sectors. Its ability to transform digital designs into physical objects offers immense potential for creativity, innovation, and problem-solving. By following the step-by-step guide provided in this comprehensive blog post, you can start your journey into the world of 3D printing, creating incredible objects and contributing to the ever-expanding 3D printing community.

Disclaimer: The images used in this blog post are for illustrative purposes only and do not necessarily represent specific products or brands.

References: